Molloy DSG Professional Digest

Regularly Updated Content for Leaders & Experts

Software and Hardware Automation in Business Process

Strategic business development through software and hardware automation involves leveraging advanced technologies to enhance efficiency, streamline operations, and create new opportunities for growth. Automation in both software and hardware forms can significantly transform business processes, enabling companies to scale operations, reduce costs, and improve the quality of their products and services. As businesses face increasing competition and rapidly changing market demands, integrating automation into their strategic planning becomes a crucial component of sustained growth and innovation.

Software automation primarily involves the use of software tools and applications to automate repetitive tasks, data analysis, and decision-making processes. This can include everything from customer relationship management (CRM) systems and enterprise resource planning (ERP) software to robotic process automation (RPA) that automates routine administrative tasks. By automating these processes, businesses can free up human resources to focus on more strategic activities, such as innovation, customer engagement, and strategic planning. Additionally, software automation improves accuracy and reduces the risk of human error, leading to higher quality outputs and more reliable business operations.

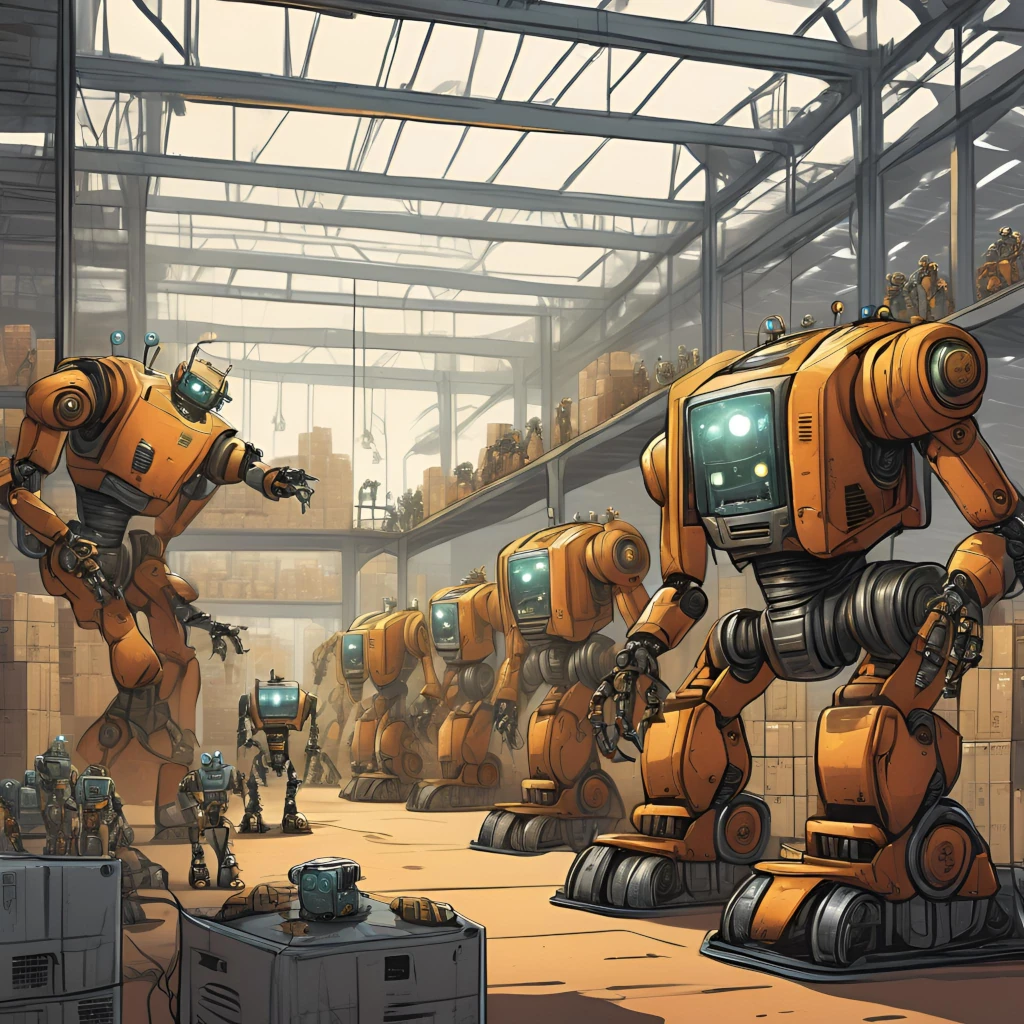

Hardware automation, on the other hand, encompasses the use of physical devices and machinery to automate manufacturing, logistics, and other physical processes. This includes technologies like robotics, automated guided vehicles (AGVs), and smart sensors that can monitor and control production processes in real-time. Hardware automation can significantly increase production capacity, improve precision, and reduce labor costs. For example, in manufacturing, automated assembly lines can operate continuously with minimal human intervention, leading to faster production times and reduced costs. In logistics, automated warehousing systems can optimize storage and retrieval processes, improving efficiency and reducing the time products spend in transit.

The integration of software and hardware automation also enables businesses to harness the power of data analytics and artificial intelligence (AI). Automated systems generate vast amounts of data that can be analyzed to gain insights into operational performance, customer behavior, and market trends. AI and machine learning algorithms can process this data to identify patterns, predict outcomes, and inform decision-making. This data-driven approach allows businesses to optimize their operations, tailor their products and services to meet customer needs, and respond swiftly to changing market conditions. It also facilitates proactive maintenance and quality control, reducing downtime and ensuring consistent product quality.

Automation supports strategic business development by enhancing scalability and flexibility. Automated systems can be easily scaled up or down to meet changing demand, allowing businesses to respond quickly to market opportunities without the need for significant additional resources. This scalability is particularly important in industries with seasonal fluctuations or rapidly evolving technologies. Additionally, automation enables businesses to operate more flexibly, adapting their processes and production lines to accommodate new products, services, or business models. This flexibility is a key competitive advantage in today's fast-paced business environment, where the ability to innovate and adapt is crucial for long-term success.